iPhone 18 Power Play: Apple Secures Half of TSMC’s 2nm Chip Capacity

TSMC

TSMC

Toggle Dark Mode

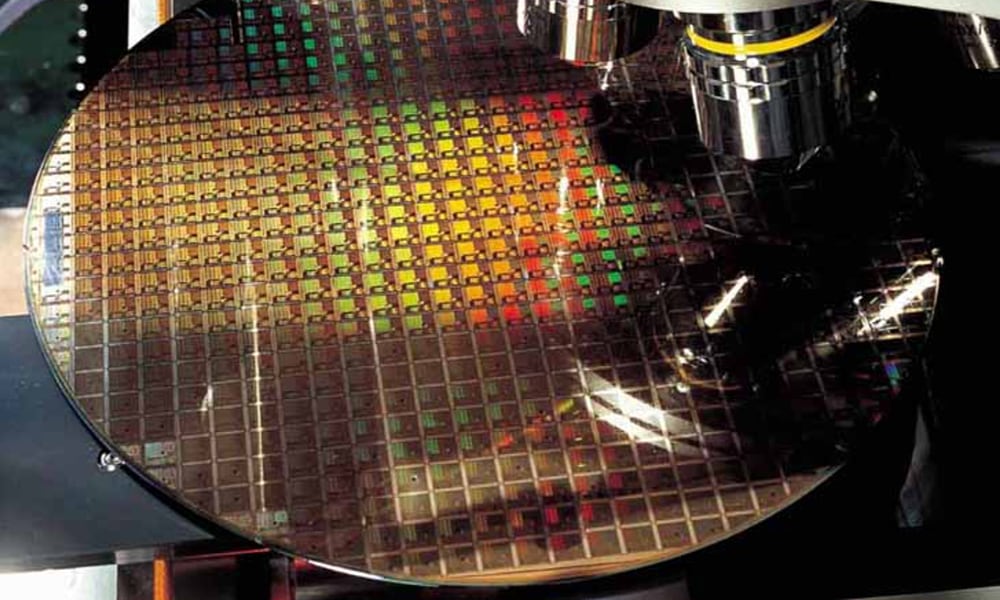

Apple has secured nearly half of Taiwan Semiconductor Manufacturing Company’s (TSMC) initial 2-nanometer (2 nm) production capacity for the A20 chip, which is expected to power the iPhone 18, as the chip foundry nears mass production of chips based on its next-generation process.

According to DigiTimes, TSMC’s 2 nm process is scheduled to begin mass production in the fourth quarter of 2025, as planned. The foundry is setting substrate pricing at an eye-watering US$30,000 per wafer. Despite the high price, chip manufacturers including AMD, Apple, Broadcom, Intel, Qualcomm, and MediaTek are scrambling to secure a piece of the Taiwan-based semiconductor manufacturer’s production capacity.

The chipmaker’s 2 nm process is expected to deliver a significant leap in both performance and power efficiency compared to the 3 nm technology used in Apple’s recent A-series chips, offering up to 15 percent faster performance and 30 percent better power efficiency than the A19 chips anticipated for use in iPhone 17 models.

The advanced 2 nm process enables higher transistor density, which is expected to enhance processing capabilities and improve battery life for Apple’s A20 chips. Analysts Ming-Chi Kuo and Jeff Pu have both predicted that the iPhone 18 lineup’s A20 chip will be fabricated using TSMC’s first-generation 2 nm (N2) process. Today’s DigiTimes report all but confirms that Apple will use the more advanced silicon wafer fabrication technology.

In addition to Apple and the other companies listed above, NVIDIA, Amazon’s Annapurna, Google, and several other major clients are expected to be added to TSMC’s 2 nm customer list by 2027. TSMC is accelerating its expansion plans and expects to be at full capacity sometime in 2026.

While electronics companies are facing uncertain economic waters these days, thanks to tariffs and other price hikes, TSMC recently raised its full-year US dollar revenue forecast from 25% to 30%, thanks to strong demand for AI and high-performance computing (HPC) chips. The company continues to fully utilize its 5 nm, 4 nm, and 3 nm production capacities.

While supply chain operators had once thought TSMC’s competitors, including Samsung and Japan’s Rapidus, might be able to snatch orders away from the chipmaker, it has proven resilient and is continuing to advance the 2 nm process as planned. The Hsinchu Baoshan F20 plant and the Kaohsiung F22 plant are key facilities for 2-nanometer production. Both factories commenced construction in 2022 and are expected to be operational by 2025.

These Baoshan and Kaohsiung facilities are expected to produce approximately 45,000 to 50,000 2-nanometer wafers per month by the end of 2025, scaling to over 100,000 wafers per month in 2026. Including production from TSMC’s plants in Arizona, USA, the total monthly capacity for 2 nm chips is expected to reach approximately 200,000 wafers by 2028.

TSMC has emphasized several times that the mass production curve for 2 nm chip technology is similar to that of 3 nm, meaning the number of product design finalizations (tapeouts) during the first two years will exceed those of both 3 nm and 5 nm in the same period.

Apple is expected by some to unveil its iPhone 18 Pro lineup in fall 2026, debuting the base iPhone 18 and entry-level iPhone 18e the following spring.