How Much Does it Cost to Make an iPhone 6s?

Toggle Dark Mode

When the iPhone 6s and 6s Plus arrived to consumers, popular gadget repair site iFixit was quick to break down the devices to see how they worked.

iFixit‘s teardowns are very informative for the curious iPhone user, as they reveal previously unknown details about the components that make up the device. However, aside from perhaps serving as a reference guide for daring DIY-ers, the guides usually don’t serve much of a purpose besides satisfying curiosity. A new teardown of the 6s Plus, however, is making headlines across the internet, this time from research firm IHS.

Image Courtesy of iFixit

Image Courtesy of iFixit

The firm performed their own teardown, but this time with the intent of estimating just how much it costs to manufacture the device.

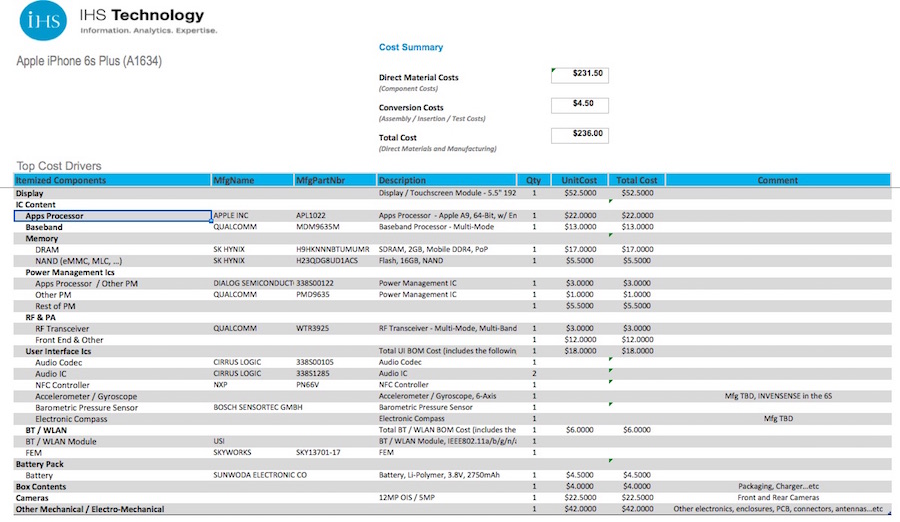

Drawing on their extensive knowledge of the electronics component industry, IHS pried apart the 6s Plus and estimated the cost of each internal component, as well as manufacturing costs. After careful analysis, IHS determined that it costs Apple roughly $236 to manufacture an iPhone 6s Plus, less than a third of the retail price of $749.

According to IHS, Apple spends roughly $231.50 on materials and $4.50 on assembly. It’s important to note that the $236 price tag doesn’t take into account a host of other costs – “from shipping and warehousing, to research and development and marketing,” IHS Senior Research Director Andrew Rassweiler told Re/Code. The estimate still gives good insight into roughly how much Apple spends on manufacturing each phone.

How much more does it cost to make an iPhone 6s Plus than an iPhone 6 Plus? Roughly $16, according to IHS. The 6s Plus features a stronger aluminum-alloy casing (likely in an effort to avoid another bendgate), as well as a new 3D-Touch compatible display, new processor, more durable shatter-proof glass, and gaskets that aid in water resistance.

All of these new features, however don’t add up to much when it comes to manufacturing costs. The most expensive upgrade, according to IHS, is the addition of the touch-sensitive displays and haptic feedback system, both of which total up to about $10 more in manufacturing costs when compared to the iPhone 6 Plus.

IHS Cost Estimate

IHS Cost Estimate

IHS noted that it hasn’t yet had time to teardown the iPhone 6s yet, but provided an initial estimate of roughly $211.50 in component and assembly costs. Although Tim Cook would likely disagree with these estimates, as he did when IHS tore down the Apple Watch – Cook was quoted as saying that he has yet to see a cost estimate that “is anywhere close to being accurate” – it’s safe to say that the estimate is at least in the right ball park.

According to IHS, the Samsung Galaxy S6 Edge, one of the iPhone’s main competitors, costs roughly $290.45 to manufacture, with a sale price of $700. Apple has not yet commented on the teardown or the price analysis.