From Powder to Watch: Apple’s Shift to 3D-Printed Titanium

Toggle Dark Mode

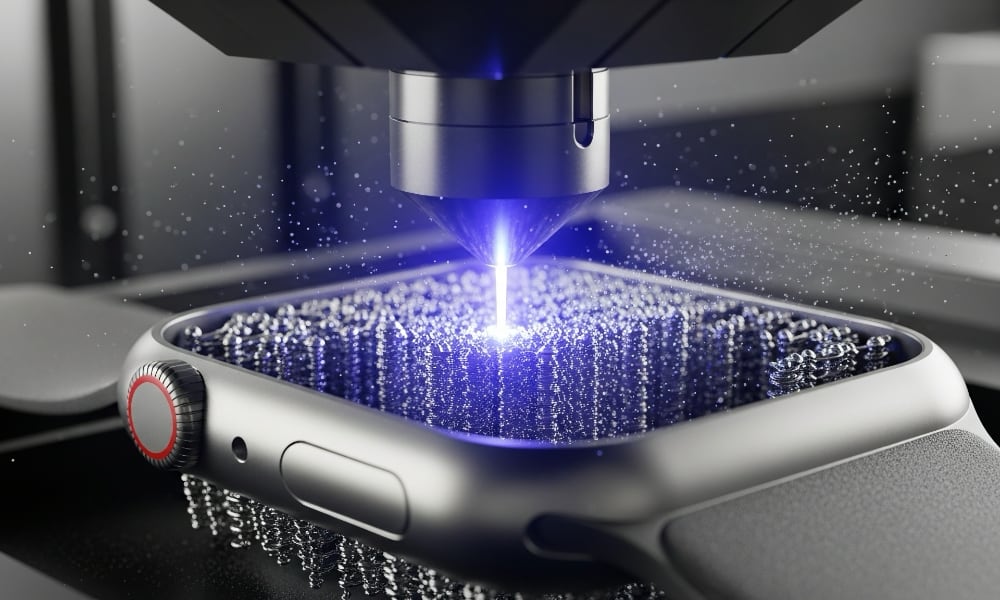

Apple has reportedly been exploring 3D printing techniques for a couple of years, and this week the company finally shared more details, proudly announcing that the cases for all of this year’s titanium Apple Watch models are now 3D-printed.

While Apple doesn’t provide a specific backstory, an August 2023 report from Bloomberg’s Mark Gurman suggests Apple likely began prototyping the idea during the Apple Watch Series 9 cycle — testing 3D-printed cases on select stainless steel models. A few weeks before that, analyst Ming-Chi Kuo indicated the process might be used to manufacture “some of the titanium mechanical parts” for the Apple Watch Ultra 2.

Apple does say the initiative began with a “pie-in-the-sky idea,” as 3D printing has historically been used only for prototypes, not at the scale of mass production for the Apple Watch. The challenge was developing a 3D printing technique that reliably produces millions of identical enclosures.

It wasn’t just an idea — it was an idea that wanted to become a reality. Once we asked the question, we immediately started testing it. We had to prove, with continuous prototyping, process optimization, and a tremendous amount of data gathering, that this technology was capable of meeting the high standard of quality we demand.

Kate Bergeron, Apple’s vice president of Product Design

For Apple, there was a second critical component: using quality recycled materials. One of Apple’s motivations for pursuing 3D printing is to advance its environmental initiatives and improve efficiency by reducing waste. The company is aiming to be carbon neutral across its entire footprint by 2030.

“At Apple, every team holds environment as a core value,” says Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation. “We knew 3D-printing was a technology with so much potential for material efficiency, which is critical for getting to Apple 2030.”

However, the most striking aspect of Apple’s titanium 3D printing process isn’t just that it uses “recycled aerospace-grade titanium powder,” but that it actually lets Apple produce a watch casing with only half of the materials previously required.

A 50 percent drop is a massive achievement — you’re getting two watches out of the same amount of material used for one. When you start mapping that back, the savings to the planet are tremendous.

Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation

Apple estimates this new process will save more than 400 metric tons of raw titanium this year alone.

There are plenty of other technical marvels wrapped up in this process, as Apple explains in its press release, from working with powder that’s only 50 microns in diameter — thinner than a human hair — and dialing in multiple layers at exactly 60 microns each to printing textures in locations that were previously inaccessible in the forging process. Apple also has to scale the entire process up to produce hundreds of thousands of Apple Watches per day. “This was cutting-edge materials science,” says Bergeron.

The Apple Watch is also just the start. Apple said it’s already leveraged 3D printing to create an incredibly thin titanium-enclosed USB-C port for the 5.6 mm iPhone Air that offers unprecedented durability, and it expects to take it even further. “We’re extraordinarily committed to systems change,” says Chandler. “We’re never doing something just to do it once — we’re doing it so it becomes the way the whole system then works.”