Apple Commits to Spending $500M on US Rare Earth Magnets

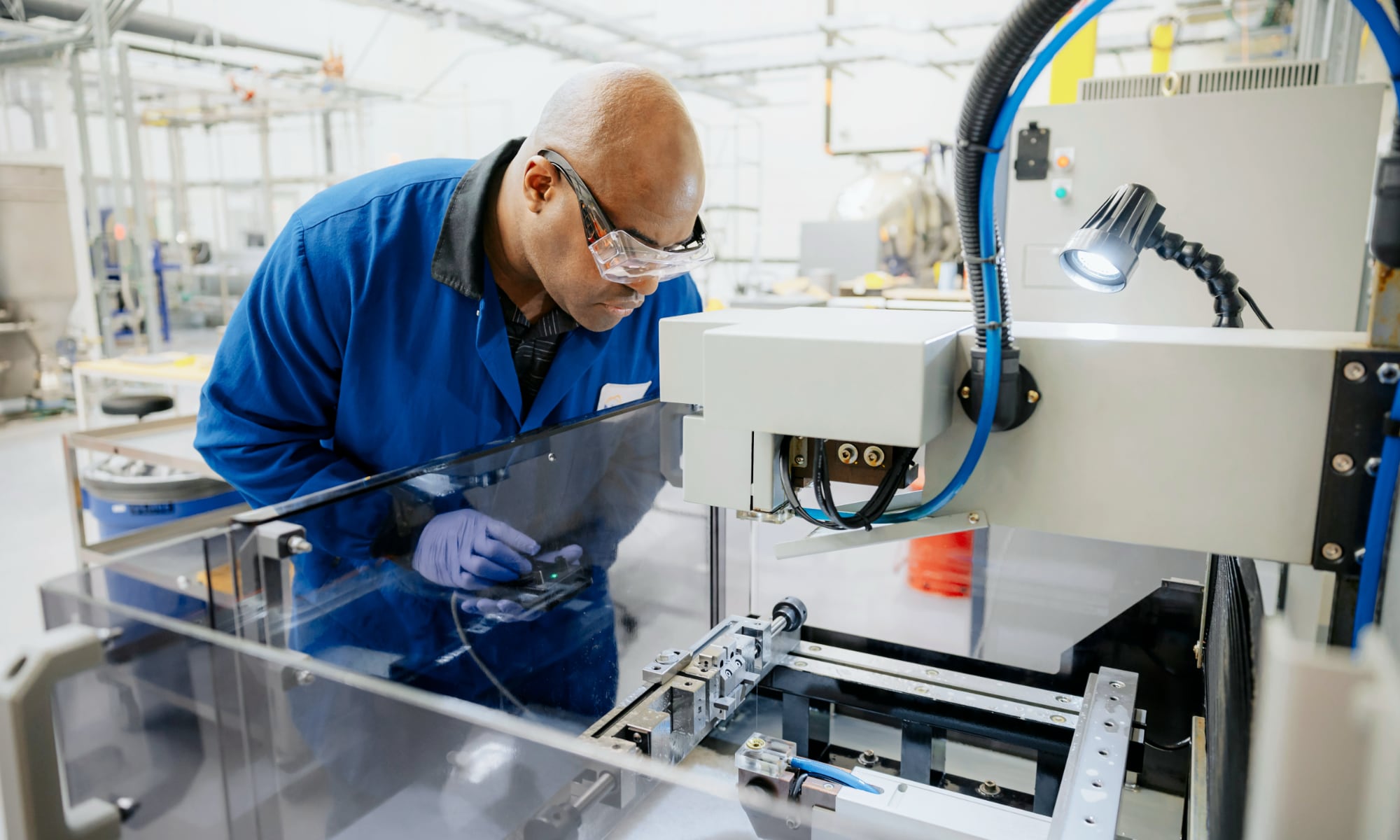

A rare earth magnet being inspected at MP Materials' Independence facility in Fort Worth, Texas [MP Materials]

A rare earth magnet being inspected at MP Materials' Independence facility in Fort Worth, Texas [MP Materials]

Toggle Dark Mode

In February, Apple pledged to invest $500 billion in the US economy over the next four years, and now it’s making good on a small part of that promise with a supply chain expansion that will see it sourcing more rare earth magnets from within the United States.

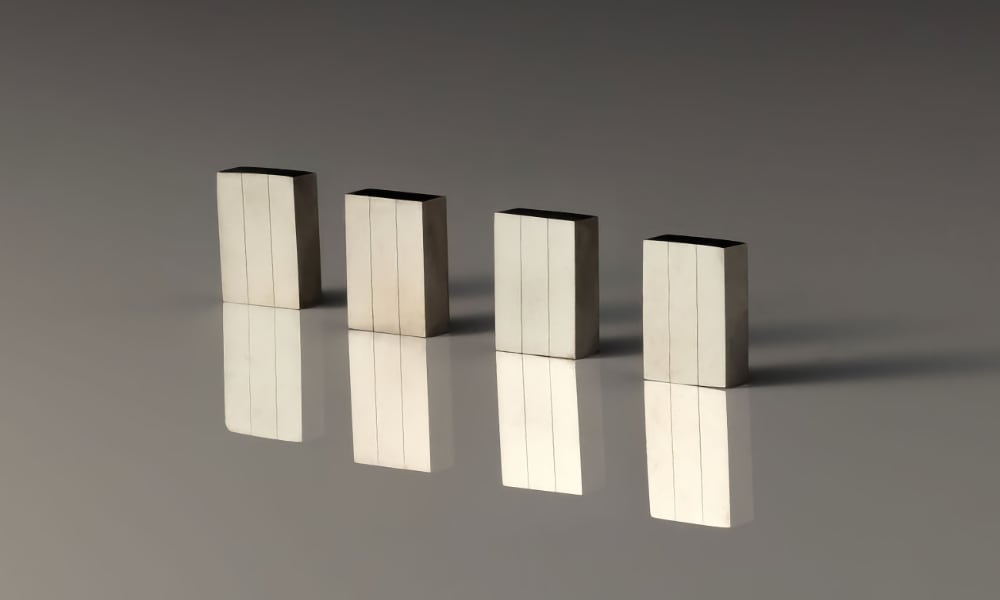

In a press release earlier today, Apple announced that it’s committed to spending $500 million with MP Materials, “the only fully integrated rare earth producer in the United States,” in a multiyear deal that will see it buying American-made rare earth magnets to use in its products.

MP Materials develops these magnets at a facility in Fort Worth, Texas, but will also work with Apple to establish a high-tech rare earth recycling plant in Mountain Pass, California, where they’ll research more advanced materials and processing technologies to create even better magnets.

American innovation drives everything we do at Apple, and we’re proud to deepen our investment in the U.S. economy. Rare earth materials are essential for making advanced technology, and this partnership will help strengthen the supply of these vital materials here in the United States. We couldn’t be more excited about the future of American manufacturing, and we will continue to invest in the ingenuity, creativity, and innovative spirit of the American people.

Tim Cook

Apple’s investment will enable MP Materials to expand its Texas factory with specialized neodymium magnet manufacturing lines for Apple devices, while also allowing the company to boost its overall production. This will result in American-made magnets that will not be used only for Apple products, but also shipped worldwide to be used in other companies’ supply chains. As MP Materials states in its press release, this will also support its public-private partnership with the US Department of Defense.

We are proud to partner with Apple to launch MP’s recycling platform and scale up our magnetics business. This collaboration deepens our vertical integration, strengthens supply chain resilience, and reinforces America’s industrial capacity at a pivotal moment.

James Litinsky, Founder, Chairman, and CEO of MP Materials

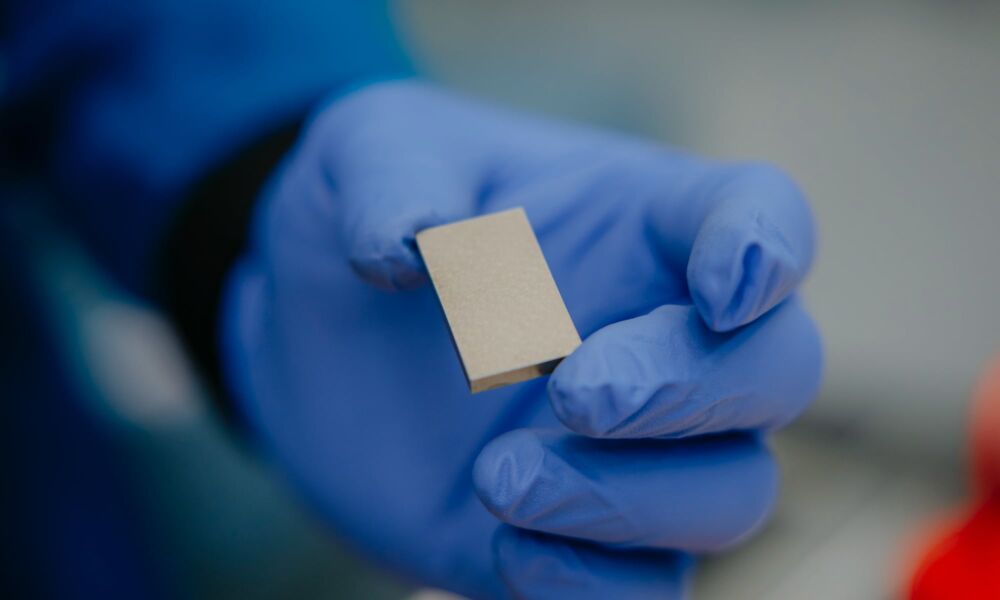

Meanwhile, the recycling facility in Mountain Pass will accept “recycled rare earth feedstock” from various sources, including used electronics and post-industrial scrap, and reprocess it for use in Apple products.

Apple has been working with MP Materials for nearly five years to develop advanced recycling technology for rare-earth magnets. Apple uses almost 100% recycled rare earth elements in products like the iPhone, and the collaboration with MP Materials will not only boost the US economy by creating jobs and new talent and expertise in this area, but will also reduce Apple’s reliance on foreign sources such as China, where trade wars risk cutting off access to critical rare earth minerals.

“This agreement advances MP’s mission to restore the full rare earth supply chain to the United States while raising the global standard for sustainable production,” MP Materials notes, adding that rare earth magnets are essential to nearly all modern electronics today, from smartphones and computers to vehicles, robotics, and energy systems.

Apple continues to face pressure from President Donald Trump to build iPhones in the US. While that’s still unlikely to happen anytime soon (if ever), this move may give the Trump administration at least a small checkmark in the win column by reducing a few of its controversial ties to China.