Apple Chip Production Gains Momentum at TSMC’s US Plants

TSMC

TSMC

Toggle Dark Mode

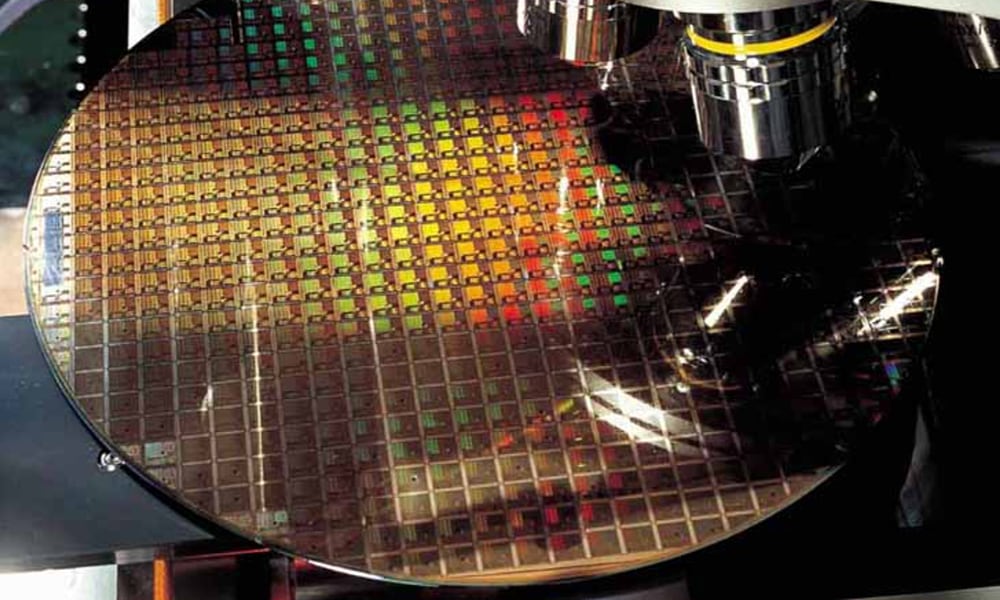

Earlier this year, Apple’s chipmaking partner, Taiwan Semiconductor Manufacturing Company (TSMC), began mass production of Apple’s first made-in-America chips, a move that culminated five years of planning and construction of a new facility in Arizona. Now, TSMC is accelerating the construction of two additional US plants to produce even more Apple silicon.

In 2020, TSMC committed to a $12 billion investment in Phoenix to build an “advanced semiconductor manufacturing fabrication” facility. That amount later increased to a staggering $40 billion when it committed to a second facility in the state.

After acquiring 1,129 acres of land in late 2020, TSMC broke ground for the first plant in April 2021 and finished it in late 2022. In 2023, it continued with plans for the second facility and began preparing to build a third not long after.

TSMC’s first plant was initially focused on fabricating 5-nanometer chips for products other than Apple’s, but by the middle of 2024, it had brought the quasi-4nm N4P process online for the A16 chips used in the iPhone 14 Pro and iPhone 15 models.

While this seemed like an odd choice, as the iPhone 14 Pro had already been discontinued and the iPhone 15 was already last year’s news, the method to Apple’s madness became apparent not long after the A16 fabrication line came online in January, when Apple surprised everyone with a 2025 iPad that featured the A16 chip. Apple is also reportedly producing S9 chips at the Arizona facility, which is currently only used in the Apple Watch Ultra 2, but could also be used in a new HomePod mini later this year.

Nevertheless, all of Apple’s flagship chips, like the A18 series and everything that starts with the letter “M,” are still fabricated at TSMC’s considerably more advanced facilities in Taiwan. However, that might change, as Nikkei Asia reports that TSMC is speeding up the construction plans for its next two facilities by “several quarters.”

This follows a March announcement that the Taiwanese company plans to build five new factories in the US, three of which will be new chip fabrication plants, although it’s unclear if these are in addition to the two that are already in the works. TSMC also plans two advanced packaging facilities and a major research and development center.

Those two packaging facilities are crucial to a fully US-integrated production pipeline. Fabrication is only part of the process, as it only handles the raw silicon production. Until those two new facilities are ready, it’s necessary to ship the US-made chips back to Taiwanese plants to be packaged into their final form.

That may be partly why TSMC is ramping things up, but it sounds like the two fabrication plants are still the priority, as demand increases for more advanced chips that can’t yet be fabricated domestically.

“After completion, around 30% of our 2-nanometer and more advanced [chip] capacity will be located in Arizona,” TSMC Chairman and CEO C.C. Wei told investors and reporters, “creating an independent, leading-edge semiconductor manufacturing cluster in the US.” The goal, Wei says, is to meet the demand for smartphone and AI computing chips with US-based production.

To put this into perspective, TSMC is already fabricating 2-nanometer chips at its facilities in Taiwan. That capability isn’t expected to arrive in the US until the company finishes its third plant, which broke ground in April and wasn’t originally expected to be ready until 2030. That puts the US facilities five years behind those in Taiwan. However, faster investment could shave a couple of years off that, which would allow leading-edge Apple silicon to be made in the US by the time the iPhone 21 arrives.

Nevertheless, Apple will still need to source chips from TSMC’s Taiwan facilities for a few more years. The A18 and A18 Pro already utilize a 3-nanometer process, which won’t be operational in the US until the second facility is completed. That’s expected in 2028, and even with TSMC’s promise to accelerate that by “several quarters,” it likely won’t be ready before late 2026 or early 2027. By that time, Apple will likely be using a 2-nanometer process for the A20 chips in its iPhone 18 models.